Pullulan is a natural, water-soluble polysaccharide from sucrose, glucose, or starch hydrolyzate through microbial fermentation and biochemical extraction. It is odorless and tasteless and is in the form of white powder. It has good film-forming, anti-oxidation, safe and non-toxic properties, and has been widely used in medicine, food, cosmetics, and other fields.

The carbohydrate carbon sources commonly used in the production of pullulan are sucrose, glucose, and starch hydrolyzate, among which sucrose is the ideal raw material for the production of pullulan, which can obtain higher yield and purity. However, organic starch is generally used as a carbon source if you want to get organic pullulan.

The fermentation strain used in the production of pullulan polysaccharide is A. pullulans, an extracellular polysaccharide produced by fermentation of A. pullulan. The production principle is that general microorganisms will secrete macromolecular polysaccharides and wrap them around to form a protective film to prevent water loss and foreign intrusion.

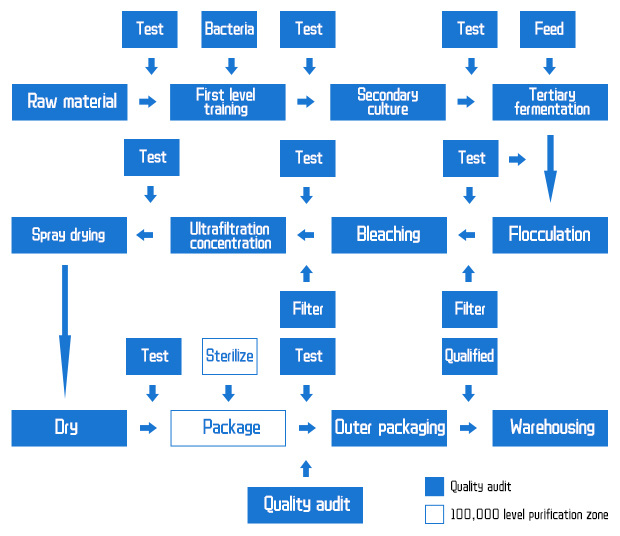

The production process of pullulan is roughly divided into several steps: bacterial culture, bacterial fermentation, flocculation, filtration, decolorization, concentration, drying, and packaging.

1. Bacterial culture:

After ultraviolet and nitrosoguanidine mutagenesis, strains with less melanin secretion and a high transformation rate are screened and cultured in a sterilized seed medium to obtain seed liquid.

2. Bacteria fermentation:

Pour the seed liquid and the sterilized fermentation medium into the fermenter together, and then add sucrose, glucose, or starch hydrolyzate for fermentation to obtain liquid pullulan.

3. Follow the steps of flocculation, filtration, decolorization, concentration, and drying to obtain white powdery pullulan.

4. Packaging and storage.

Baoding Fei Sifu Industry and Trade Co., Ltd. is a professional manufacturer of pullulan polysaccharides. It has six pullulan polysaccharide production lines with an annual output of 3,000 tons. The complete production line is independently developed by our company, with high-end equipment configuration and a high degree of automation control. OEM and ODM can be customized according to customer requirements.